As global leaders gather at COP30 to accelerate climate action, a new study by Innoval Technology, a UK-based aluminium consultancy, highlights how can-to-can recycling of aluminium beverage cans delivers major environmental gains and advances circular economy goals.

The study finds that recycling used beverage cans back into new cans through dedicated remelt operations could increase melt recovery rates by 18% and cut energy use and greenhouse gas emissions by 15% compared to mixed-alloy recycling.

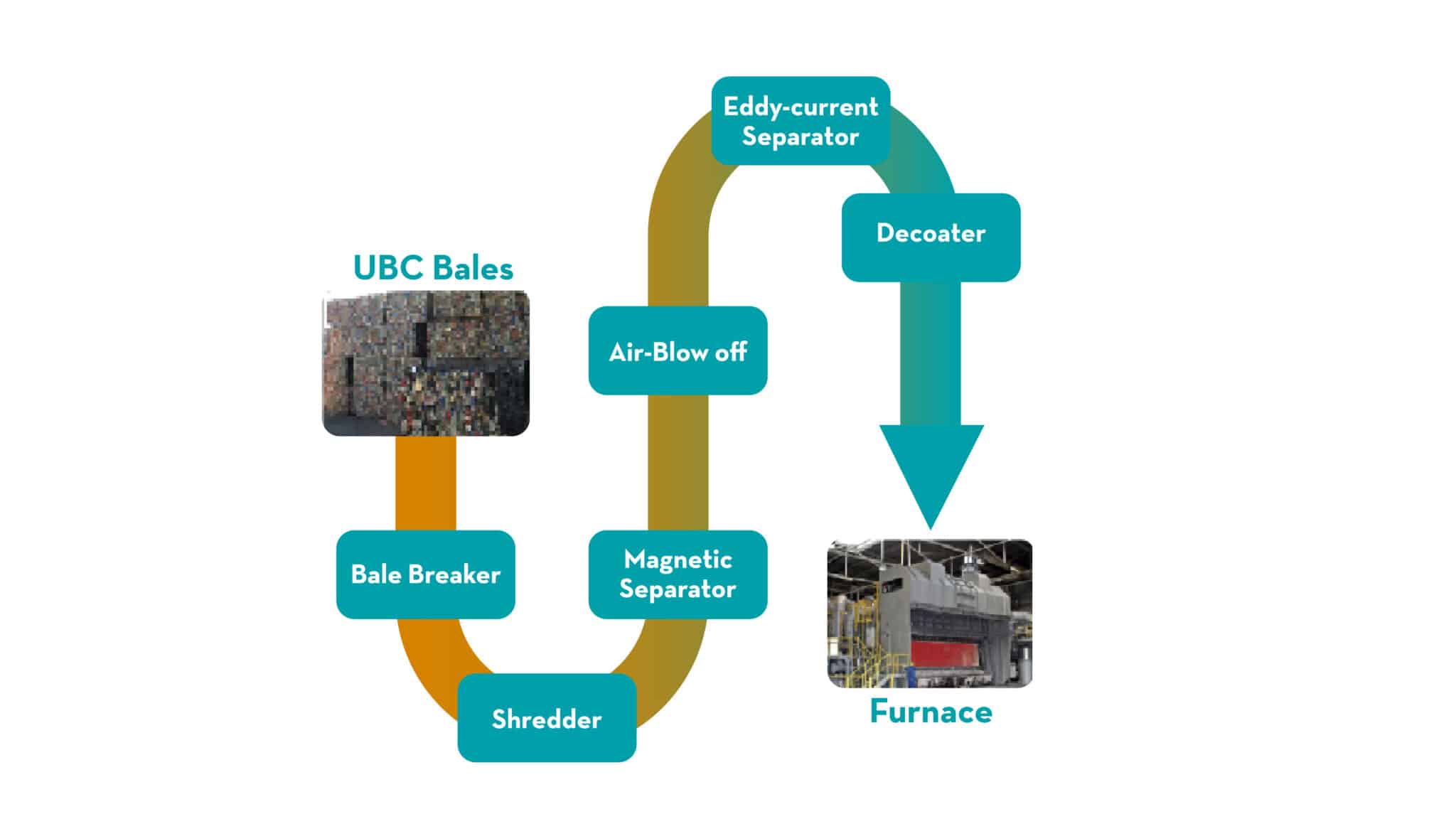

Today, 23% of the aluminium beverage cans are leaked and recycled into cast aluminum components, such as engine blocks for vehicles. However, reversing this process is not economically viable due to the fundamentally incompatible chemical composition of the two-alloy type. To produce 1,000 kilograms of can-grade aluminum sheet from cast alloys, remelters would need to dilute the material with roughly 980 kilograms of primary aluminum to correct elevated silicon levels—making the process both resource-intensive and cost-prohibitive. Aluminium cans already demonstrate one of the highest circularity rates of any packaging material. Used cans are continuously recycled into new cans without quality loss, made possible by advanced alloy design, precise metallurgy, and efficient processing.

The research also shows that greater closed-loop recycling could deliver an additional 50% reduction in Greenhouse Gas emissions for aluminium cans, if 87% of recycled cans are returned to can production rather than other markets. This would require no changes to the remelting infrastructure and represents a major opportunity for the aluminium beverage can value chain to reduce its carbon footprint.

Expanding Deposit Return Systems (DRS) across the EU and UK by 2030 is expected to improve scrap quality and enable higher recovery rates, supporting this transition.

Industry Perspectives

Innoval Technology:

“Innoval is delighted to work with leading stakeholders across the aluminium beverage can value chain in the build up to COP30. This study highlights can-to-can recycling as both a critical climate solution and an optimised engineering success. By controlling metallurgy and processing, the industry can unlock significant environmental benefits while maintaining quality.” — Mike Clinch, Innoval Technology

Ball Corporation:

“Increasing the circularity of aluminium cans is central to both sustainability goals and the economics of our value chain. The evidence makes it clear: investment in advanced recycling technologies is essential to cut emissions and drive a low-carbon future.” — Ramon Arratia, Ball Corporation

Heineken:

“Our commitment to sustainability means ensuring our packaging remains in a circular economy. Closed loop recycling of our aluminium cans helps us reduce waste and emissions while supporting our 2030 target of 50% recycled content in bottles and cans.” — Sonia Thimmiah, Heineken

Novelis:

“With over 75% of aluminium beverage cans recycled globally, the next step is to improve recovery rates through can-to-can recycling. This is where metallurgy and technology combine to deliver measurable climate benefits.” — Alison Lee, Novelis

Ardagh Metal Packaging

“This study is another data point showing that can-to-can circularity has the potential to deliver a truly sustainable product with exceptional efficiency. For the beverage industry, regulators and other stakeholders, this should be a clear reason to ensure conditions are met to further increase can-to-can recycling rates and collection of used beverage cans.” — Til Ruhnke, Ardagh Metal Packaging

International Aluminium Institute (IAI):

“Understanding the linkages of the chemical composition, alloy microstructure and the properties of your final product is the foundation of driving can-to-can recycling. Innovation in recycling is key to advancing a sustainable, low-carbon future.” — Marlen Bertram, International Aluminium Institute

With aluminium beverage cans already leading in circularity and climate performance, can-to-can recycling presents a scalable, economically viable solution to support national climate commitments and industry sustainability targets being discussed at COP30.